Overview

Holon Robotics empowers robotic arms with AI-driven path planning based on 3D vision input, enabling high-precision automation for complex surface tasks such as polishing, grinding, welding, and spraying. By analyzing scanned 3D point cloud data, the system automatically generates robot paths that adapt to real-world geometry—eliminating the need for manual point teaching or offline programming.

Compared to traditional methods, which require time-consuming manual calibration and simulation, Holon's solution reduces robot path generation time by up to 85%, dramatically accelerating deployment and minimizing production downtime. This real-time adaptability also removes the burden of part variation and re-teaching when switching workpieces.

At the core of the platform is a real-time adaptive path engine that integrates with multi-axis robotic arms and sensor arrays. By continuously refining trajectories based on vision and sensor data, Holon Robotics achieves sub-millimeter positional accuracy without halting operations—ensuring both performance and safety in dynamic manufacturing environments.

Robotics grinding

Robotics grinding

3D scan path planning

3D scan path planning

Robotics polishing with HolonOS

Robotics polishing with HolonOS

Challenges

Deploying an industrial embedded computer in a Holon AI robotics arm presents several challenges. One of the which is the extensive I/O requirements. The arm integrates multiple high-resolution cameras from various angles for scanning and object recognition, a range of sensors (IMUs, torque, position, temperature), and numerous actuators for joint control. This demands a computer with high-speed connectivity (USB 3.0, GigE, CAN, and serial interfaces), sufficient bandwidth, and port density to support simultaneous data acquisition and control loops.

Equally important is the AI processing capability. The embedded computer must have high-performance computation capabilities and/ or the ability to add a GPU for AI model execution in real time. These models perform tasks like dynamic object tracking, path planning, and adaptive force control, requiring low-latency inference to make on-the-fly adjustments during operation.

Furthermore, industrial environments introduce significant operational hazards. The computer must be able to endure high temperatures, electromagnetic interference, dust ingress, and mechanical stresses such as vibration and shock.

Failure to address these conditions can lead to thermal throttling, signal degradation, or physical damage, jeopardizing real-time performance and system reliability.

Embedded Solution

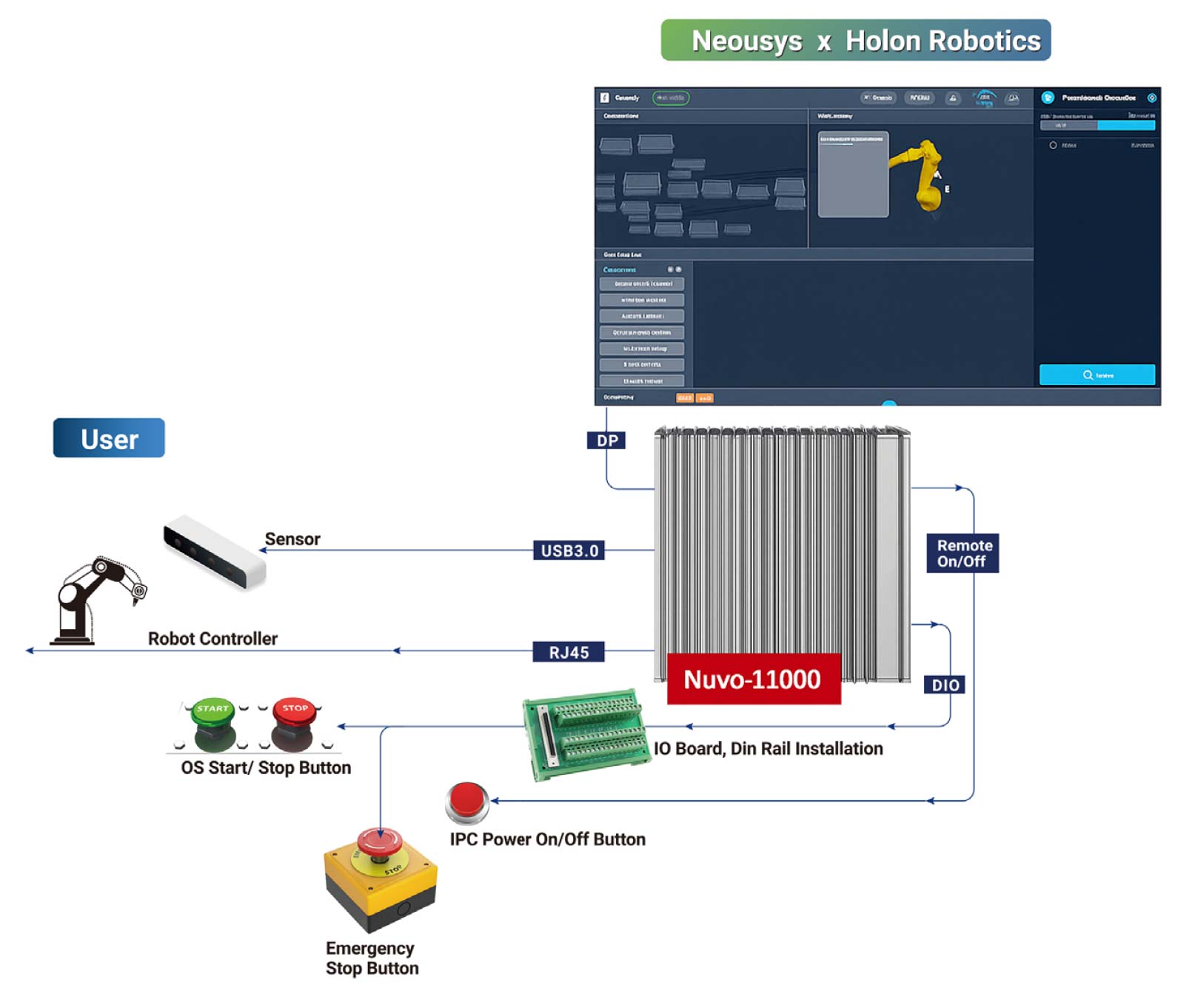

The system integrator chose Neousys' Nuvo series embedded computer, a robust and intelligent platform ideal for Holon Robotics' robotic arm applications, including real-time path planning through object detection, 3D scanning, and AI point cloud segmentation.

The latest Nuvo series from Neousys utilizes the powerful and yet efficient Intel® Core™ Ultra 200 series processor, featuring an integrated NPU (Neural Processing Unit) to offer a combine 45 TOPS AI computation. This provides efficient, low-latency edge AI inferencing that is critical for real-time robotic decision-making. For more compute-intensive AI workloads, such as advanced object recognition or simultaneous multi-sensor fusion, the fanless rugged embedded system also supports GPU add-on via PCIe slots, allowing for powerful parallel processing without sacrificing form factor or efficiency.

The system's rich I/O connectivity is a major advantage for Holon robotics. It includes multiple Gigabit Ethernet, USB 3.2, and COM ports, facilitating seamless integration with a variety of sensors, cameras, LiDAR units, and actuators. This ensures real-time data flow and coordination between components in an automated robotic environment, particularly suited for applications requiring adjustments on-the-fly.

Built for the field, the Neousys Nuvo series features a rugged, fanless design, engineered with Neousys' proprietary thermal dissipation architecture. This ensures silent, dust-free operation even in harsh industrial conditions. Its wide operating temperature range, along with shock and vibration resistance, makes it ideal for deployment on factory floors, logistics centers, and mobile robotic platforms.

- Learn more about Neousys Rugged Embedded Computers: https://www.neousys-tech.com/en/product/product-lines/industrial-computers