Overview

Robotics and machine vision are common automation applications in smart factories. The robotics system can detect and pick out machine tools and place them into storage, awaiting maintenance or restoration. With the development of Industry 4.0, building a smart factory requires intelligent robots, industrial gateways, etc. to maintain quality, consistency and manufacturing efficiency.

The robotic arm application in smart factories is a common sight. Frequently used to replace human labor in repetitive tasks, as the term “pick and place” suggest, it picks up an item from location A and places it to location B. Though a simple action, but to the human body, the repetitiveness of up to tens of thousand times a day will result in fatigue and inaccuracies. And hence, the invention of the robotic arm application that can work around the clock.

Problem-solving

As time goes by, robotic arm applications have advanced into utilizing machine vision to meet the demand to handle delicate precision tasks or items with complex shapes. Such as items with multiple geometric or reflective surfaces that would have otherwise been hard for the traditional robotic arm to handle. This issue makes it hard for the robotic arm to recognize and pick up from location A and place the item to location B.

Problem solved – VGR solution, Nuvo-7006 + LIPSLab 3D cameras

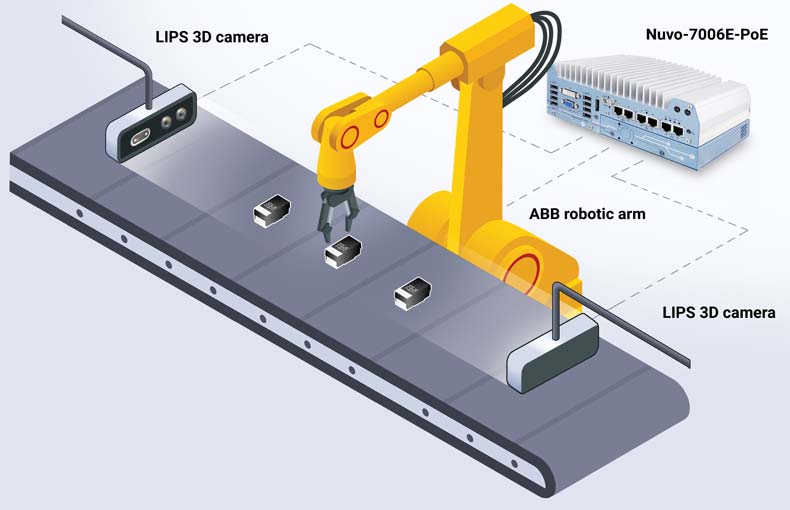

At LIPSLab, a leading expert of 3D machine vision cameras implemented 3D cameras into ABB robotic arm and Neousys Technology's Nuvo-7000 series that utilizes NIVIDIA graphics card processing power to create the "Vision Guided Robotic (VGR)" solution.

The solution consists of three laser focus 3D cameras strategically positioned to register X, Y and Z axis of the item and the Nuvo-7000 series can calculate and adjust A, B and C access and departure angle of the item. LIPSLab chose Neousys Technology's Nuvo-7000 series that can survive in compact embedded enclosures under extreme heat conditions and utilize NVIDIA graphics card's inference processing power to boost the solution's ability to recognize various geometric surfaces, size and shape. This allows the robotic arm to precisely identify the item's exact location and shape for pick up, the item can be safely retrieved and placed onto the platform.

This is a powerful hand-eye coordination solution that features ABB robotic arm (the hand), LIPSLab 3D cameras (the eye) and coordinated by Nuvo-7000 series GPU-aided computer to pick up items in non-specific positions delivered by a conveyor belt, place it accurately onto the platform for spraying, welding, deburring, deflashing or other surface treatment processes

Benefits

The LIPSLab VGR solution that features three LIPSLab 3D cameras, an ABB robotic arm and a Neousys Technology Nuvo-7006 system has the following benefits:

- The laser focus characteristic of the cameras meant that the cameras can no way be affected by the ambient light, camera's positioned direction or angle

- Machine hand-eye coordination offers greater accuracies

- Reduced processing error: items receive correct processing treatments

- Robotic arm offers 24/7 operation

- Saves labor cost in the long run

- Dramatically improves operation efficiency

Neousys Wide Temperature Embedded Systems DNA

Fanless operation

Fanless operation and efficient heat dissipation

True wide temperature operation capable

Neousys systems thrive in harsh conditions, specifically under high-temperature operations (up to 70°C).

Processing power

Nuvo-7000/ 8000 GPU-aided series systems supports 8th/ 9th Gen Intel® Core™ i CPUs

GPU-aided AI inference capability

Nuvo-7000/ 8000 GPU-aided series systems support NVIDIA® graphics cards up to 250W. Nuvo-7164GC/ 7166GC support NVIDIA® Tesla® P4/ T4 inference accelerator.

Shock and vibration proof

The system is designed to withstand operating shock and vibration conditions with patented damping brackets.

Wireless communication module and various I/O ports

Via expansion sockets, Neousys IGT series IoT gateways can install WiFi or 4G cellular modules to offer wireless communication with other nearby devices, central computer or cloud systems. The IGT series IIoT systems may also offer analog inputs (0-10V, 4-20mA), digital I/Os, CAN bus, USB, LAN, COM, etc.