Overview

A Railroad crossing accidents occur almost everyday and with the size of trains and force, accidents are usually catastrophic causing millions of dollars in damages and human casualties. The common causes of railroad accidents can be divided into two categories that include:

| Hardware factor | Human factor |

|

|

Our client's solution aims to solve some the "hardware factors" by developing a vehicle to infrastructure, and vice versa, warning system to on road vehicles. The reason is an on-road vehicle requires less warning time and distance to come to a halt than a 200-ton train.

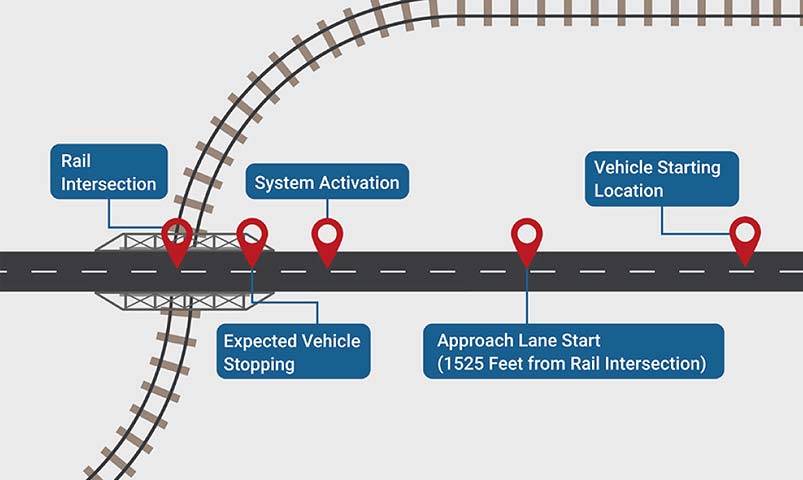

The solution features a vehicle-based subsystem (VBS)communicating constantly with the roadside-based subsystems (RBS), situated in a traffic signal cabinet deployed by the Transportation Research Center (TRC) at the test track. The system works on a IEEE 1570 communication system, the standard defines logical and physical interfaces, and the performance attributes for the data communication interfaces between the rail subsystem and the highway subsystem at a highway rail intersection. A test track length of 1525 feet (535 feet decision sight distance + 990 feet warning sign placement) to the railway stop bar was mocked up to the vehicle to simulate real world conditions.

With multiple factors considered, the pavement condition, signal stability at various speed, simulated course to actual world railway crossing, etc., the tests showed the Vehicle-to-Infrastructure Railway Crossing Violation Warning System effective. Tests were performed at a range of speeds (35, 50, 60 for trucks/ up to 70 for MDX, mph), the VBS' warning system were successfully triggered and cause the vehicles to decelerate to a full stop well before reaching the stop bar.

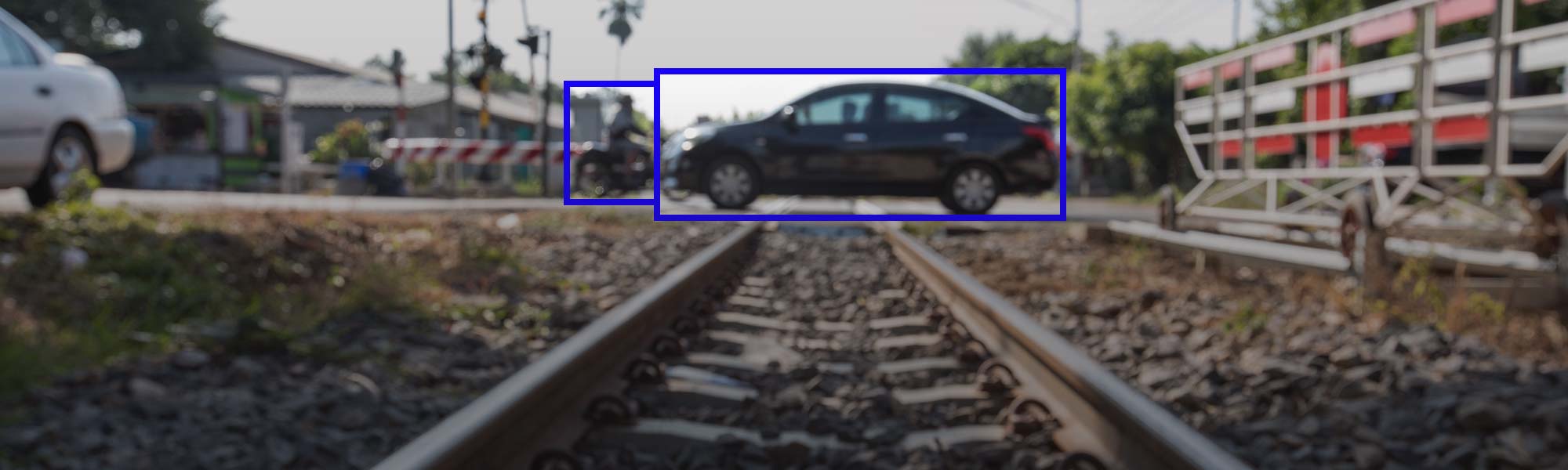

Vehicle-to-Infrastructure railway crossing violation warning system field testing

Vehicle-to-Infrastructure railway crossing violation warning system field testing

Vehicle comes to a full stop in front of rail intersection

Vehicle comes to a full stop in front of rail intersection

Challenges

Deploying computer systems on the side of a railway track is always challenging for a variety of reasons. First, the weather out in the open field. Though the computer will be placed within a cabinet along with other electronic devices,but being under the sun will dramatically soak up more heat than usual. Expect temperatures to reach 50°C+, and depending on the location, say if it is situated in the desert, it may drop to just below zero, -2°C or -3°C.

Other requirements for the system also include an Intel CPU, CAN bus, HDMI/ DVI output, USB, Ethernet connectivity, Power over Ethernet capability, 1570 serial communication, and power input acceptance.from the roadside cabinet.

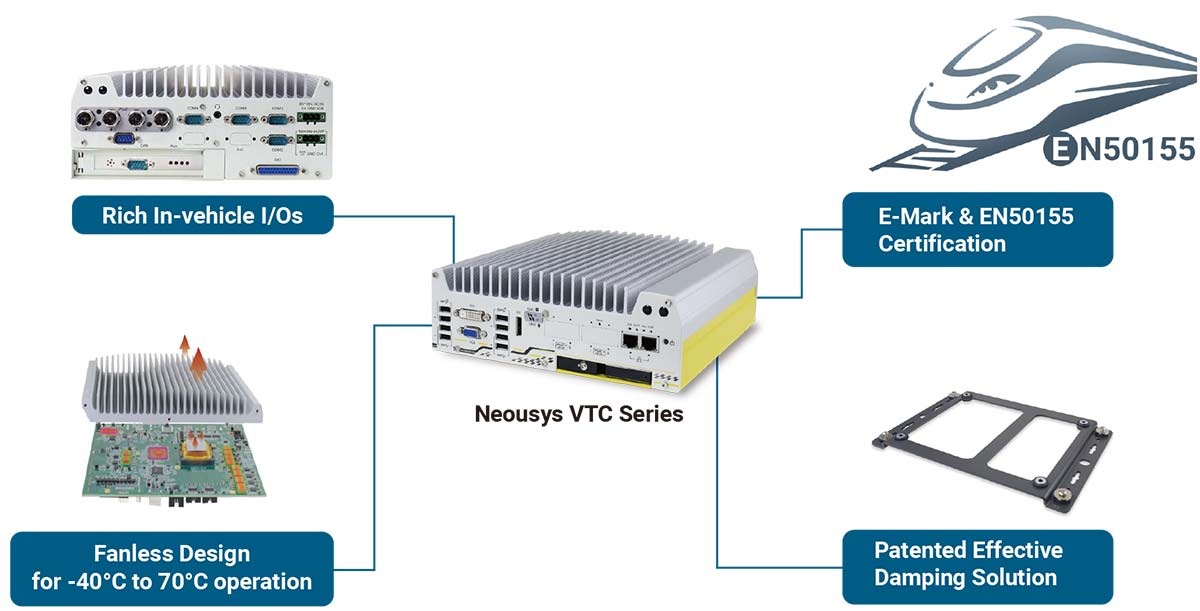

Solution

The Neousys VTC series are rugged expandable in-vehicle computers designed to withstand harsh operation environments on trucks, buses, and rolling stock. VTC series have patented heat dissipation, shock and vibration resistant design, making them extra stable during mobile operations.

Connectivity-wise, VTC series sports Power over Ethernet/ USB ports for cameras, video display output for onboard information system, expansion slots for wireless communication modules, CAN bus ports for monitoring vehicle statuses, and COM ports for connecting to onboard information devices (ticketing machines, bell system, etc.) where deploying just the one system may take care of all the needs on the bus.

The VTC platforms also feature true wide-temperature operation, ignition control, EN 50155, and E-Mark certification, it can serve as a multi-purpose gateway and meeting the demands of various in-vehicle and mass transportation applications.