When it comes to industrial computers, stability is a critical factor in ensuring seamless operations in challenging environments. And one crucial element that plays a significant role in maintaining stability is heat dissipation. But have you ever wondered why heat dissipation is so important? How does it affect the performance and reliability of industrial computers, especially in elevated temperature conditions? And why do some industrial computers handle elevated temperature environments better than others? Let's dive into the world of industrial computing and explore the fascinating relationship between heat dissipation and stability.

Key Takeaways:

- Heat dissipation is vital to maintaining stability in industrial computers operating in elevated temperature environments.

- Inadequate heat dissipation can lead to system failures, component damage, and decreased overall performance.

- An efficient heat dissipation fanless cooling design that features rugged maximized surface area with evenly-distributed heat-generating component layout contribute to enhanced stability and performance.

- Not all industrial computers heat dissipation capabilities are created equal, there's more than meets the eye

Understanding the concept of heat dissipation in industrial computers

Heat dissipation is the process of removing heat generated by the computer's components and dissipating it into the surrounding environment. It involves conduction and dissipating surface area to effectively transfer the heat away from heat generating components and maintain a safe operating temperature.

However, when not properly managed, or poor designs that are unable to deal with constant and excessive heat production, it can have detrimental effects on the stability and performance of industrial computers. Inadequate heat dissipation can result in reduced lifespan of components, compromise overall reliability, and eventually system failure.

Consequences of inadequate heat dissipation:

To emphasize the importance of heat dissipation, here are some potential consequences of inadequate heat management in industrial computers:

- System instability and crashes

- Reduced lifespan of components

- Performance degradation

- Increased risk of electronic failure

These consequences can result in costly repairs, downtime, and interruption in critical industrial processes. Therefore, industrial computers must prioritize efficient heat dissipation mechanisms to ensure stable and reliable operation in demanding environments.

"Proper heat management is crucial to prevent overheating and avoid costly system failures. Industrial computers must effectively dissipate heat to maintain stability and ensure long-term reliability."

Heat dissipation techniques for industrial computers

When it comes to industrial computers, heat dissipation is a crucial factor that directly affects stability and performance. In demanding environments, where extreme temperatures and challenging conditions are common, efficient heat dissipation becomes even more vital.

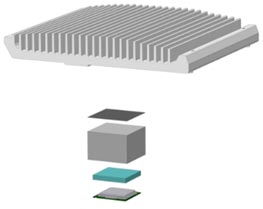

One of the primary techniques employed in industrial computers is the use of fanless conduction cooling systems coupled with heat sink for heat dissipation.

The traditional embedded design's thermal solution is governed by the existing ready-made motherboards or modules manufacturers utilize. With the CPU socket, memory modules sockets, capacitors, etc. all placed on the same PCB side, this results in component height differences. To rid of the CPU-produced heat, manufacturers must place intermediate thermal conductive materials in between to compensate for the height differences. The common design would be sandwiched as:

- A layer of thermal grease or thermal pad with a thermal conductivity rating of 5~15 W.m-1.K-1 is placed on top of the CPU integrated heatsink (IHS).

- Followed by a metallic block (copper with thermal conductivity of 401 W.m-1.K-1 or aluminum with thermal conductivity of 237 W.m-1.K-1), acting as the intermediate and to make up for the height differences.

- Finally, another thicker and softer thermal pad (approximately with less than 5 W.m-1.K-1 conductivity) makes direct contact with the external heatsink to expel the heat to the ambient environment.

Fanless computers are designed to operate without the need for traditional cooling fans, offering several advantages. First, the absence of fans eliminates noise, making fanless computers suitable for noise-sensitive environments. Second, the lack of airflow minimizes dust accumulation, reducing the risk of component damage and system failure. Last but not least, fan blades/ ball bearings are moving parts that are subject to failure, so a fanless system essentially mitigates a possible point of failure.

Comparison Table: Heat Dissipation Techniques

| Heat Dissipation Technique | Benefits |

| Rugged passive cooling |

|

| Active Cooling with Fans | Fast heat dissipation |

| Advanced Heat Pipe Technology |

|

The table above provides a comparison of different heat dissipation techniques utilized in rugged industrial computers. Each technique offers unique benefits, allowing for optimal heat management and stability in these specialized systems.

How Neousys cooling technique differs?

Neousys thermal solution seeks to deliver efficient heat transfer and dissipation with components strategically laid-out to avoid heat soak interference. The simplified and effective design is customized and fine-tuned for maximum heat dissipation efficiency that allows Neousys fanless embedded systems to thrive in extreme environmental conditions for true wide temperature operation. Neousys fanless embedded systems differ from others in a number of ways:

Heat-generating components are segregated. The Neousys design team placed all heat-generating components on the top side, along the perimeter to promote heat dissipation while avoiding heat soaking effect.

Segregated and evenly distributed to avoid heat-soak. Spacing between heat-generating components are carefully thought and evenly distributed. The in-house circuit design allows heat-generating components, including CPU, chipset, Ethernet controllers and power chokes, to be placed with desired spacing to avoid heat-soak, utilizing every inch of the heatsink.

Use of unique and extremely efficient premium-grade thermal pad. Unlike common fanless embedded systems that may have layers of heat conductive materials stacked in between, Neousys fanless embedded systems place just a single layer of thermal pad directly between the heat-generating components and the external heatsink, heat conduction ability is direct and effective.

Thermal design from the ground up. Neousys fanless embedded system is designed and tweaked for maximum thermal efficiency. In a Neousys fanless system, the mechanical design complements thermal efficacy, and vice versa to ensure the system's thermal conduction efficiency is always at the peak. This allows every Neousys fanless embedded system to be truly wide temperature operational, meaning the system can operate from -25°C to 70°C, twenty-four seven. The extremely high thermal dissipation efficiency design offers stability to the system in operation and longevity to electronic components.

Conclusion - choosing the right industrial computer

Choosing an industrial computer depends on factors like processing power, temperature range, installation space, and environmental conditions. Temperature range indicates operational stability, tied to heat dissipation capability. Efficient heat dissipation technology maintains optimal temperatures, preventing performance issues and prolonging lifespan.

Heat dissipation plays a crucial role in maintaining the stability and performance of industrial computers in challenging environments. This article has highlighted the importance of effective heat management in these systems to ensure reliable operation and minimize the risks caused by extreme temperatures.

When considering industrial computers for challenging settings, it is essential to prioritize rugged designs that incorporate efficient heat dissipation capabilities. These designs, such as system cooling designs and durable components, enable industrial computers to operate consistently and efficiently, even in harsh conditions.

Investing in reliable systems that can withstand extreme temperatures and efficiently dissipate heat will contribute to long-term operational stability and minimize the risk of system failures and component damage.

FAQ

What is heat dissipation in industrial computers?

Heat dissipation in industrial computers refers to the process of dissipating or removing heat generated during the operation of these systems. It involves the use of cooling techniques, layout design, and selection of components to maintain an optimal temperature and prevent overheating, which can negatively impact the stability and performance of the computer.

Why is heat dissipation important to industrial computer stability?

Heat dissipation is crucial to maintain stability in industrial computers because excessive heat can lead to system failures, component damage, and decreased performance. Industrial computers often operate in elevated temperature environments, so effective heat management is essential to ensure reliable operation.

What are some heat dissipation techniques used in industrial computers?

Industrial computers employ various heat dissipation techniques to manage and control heat effectively. One common technique is the use of fanless cooling systems, which eliminate noise and minimize dust accumulation. Additionally, rugged designs with efficient heat transfer capabilities, even distribution of heat-generating components, and effective heat sinks help dissipate heat efficiently, ensuring reliable operation in demanding environments.

How does heat dissipation impact performance in rugged industrial computers?

Heat dissipation plays a crucial role in ensuring optimum performance in rugged industrial computers. Efficient heat dissipation allows these systems to operate reliably in extreme temperatures, preventing overheating and thermal-throttling that result in performance degradation. Rugged designs with robust cooling systems and durable components contribute to enhanced heat dissipation, resulting in continuous and efficient performance.

How do I choose the right industrial computer for applications with elevated temperatures?

When selecting an industrial computer for wide temperature applications, it is essential to prioritize heat dissipation and stability. Consider factors such as temperature range specifications, cooling capabilities, and the ruggedness of the system. Ensure that the chosen computer has efficient heat dissipation mechanisms to withstand the demanding conditions and maintain reliable operation. There are lots of brands and designs to choose from on the market, but not all industrial computers are created equal, so a word of mouth from people who have tried and tested various systems may also help narrowing down the list.