Overview

Machine vision has long pervaded the automotive manufacturing industry, ensuring quality consistency in process and increasing overall production efficiency. As many systems deployed in early years have become aged and problem-prone, technology advancements have enabled more flexible and expandable solutions. Flexible in that minimum hardware adjustments can be incorporated, and expandable in continued investments can be made to maximize ROI.

For instance, a Tier 2 automotive supplier's previous system used vibratory bowl feeders to sort and orient parts for a robot to pick. When it became too rigid and error-prone, they decided to seek for a new system that could inspect mixed models. However, introducing a new part into the process would usually require adding a new bowl feeder and entail floor space issues.

They hired system integrator, an automation expert with a wealth of proven successes, tapped the advantages of Neousys' Nuvo-9000 series fanless embedded computer and PB-9250J-SA power backup module and developed a high performance and versatile automated inspection system that can inspect up to 15 different auto part types simply by choosing or resetting recipes over an HMI instead of changing processes and hardware, with virtually the same system footprint of the legacy system.

Automated inspection system

Automated inspection system

Human machine interface (HMI)

Human machine interface (HMI)

Challenges

With the increase in vehicle maintenance needs, do car manufacturers add on more service personnel? This would also mean additional service workstations, requiring more real estate and equipment. What if we can effectively and efficiently increase the rate of vehicle maintenance while sustaining inspection quality? The solution need to be able to perform maintenance tasks a normal service staff would, this includes checking for exterior and undercarriage defects.

Solution

The automotive industry has been undergoing dramatic changes in recent years with new breeds of cars hitting the market—such as electric cars and autonomous vehicles. To adapt to the exponentially increasing demands and custom orders, auto parts suppliers need more dynamic and flexible systems to test and inspect a wide range of products. More compact systems with higher performance and more features are preferred, as floor space is always limited.

As auto parts manufacturing is among the first industries to adopt automation in early years, many systems in the field are still based on traditional PLC control systems, a shift to PC-based platform is absolutely needed for more flexible and capable programming to enable features such as remote control, process visualization and data pooling.

The use of PC also provides a platform for connecting up PLCs and other existing equipment in the facility to structure an industrial IoT system which will continue to pave the way for increasing Industry 4.0 practices. The preparation for Industry 4.0 is important, as process transparency and data traceability has become a prerequisite for certain quality standards, and intelligent manufacturing is becoming industrial status quo.

Solution

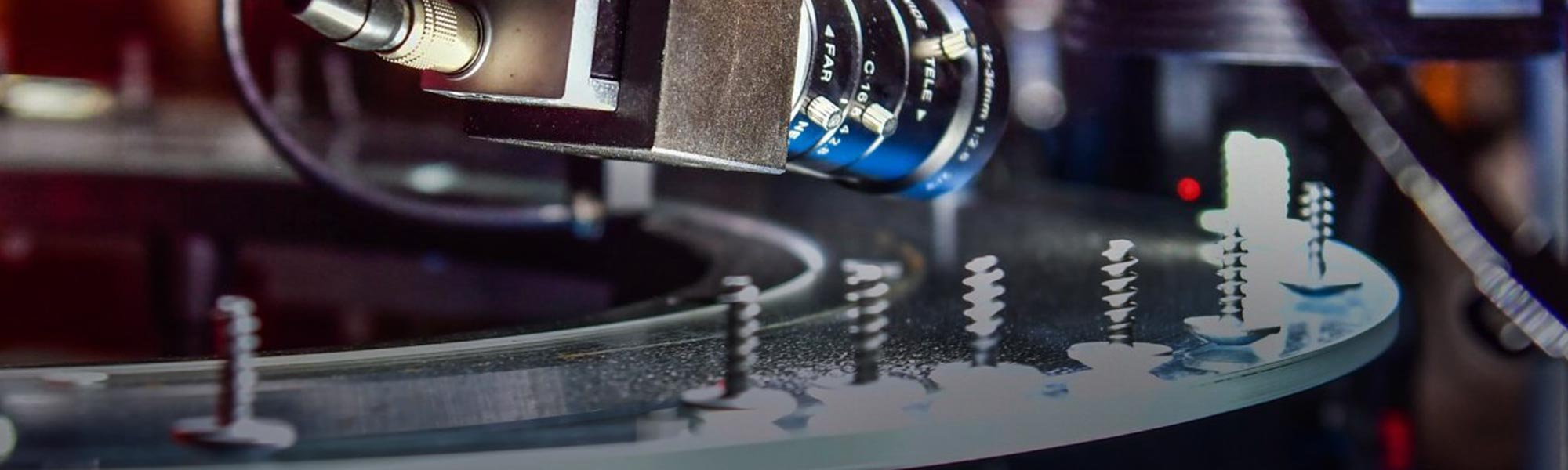

The SI developed an entirely new inspection system incorporating industrial cameras, robots, flexible part feeders and vision software.

At the heart of the system sits a Nuvo-9000 rugged embedded computer connecting to five GigE cameras, two of which comprises the inspection station providing two views from different angles during inspection; another two cameras look down over the flexible bowl feeders to inform the robot of pick locations; while the last camera provides barcode verification at the end of the process.

A set of custom machine vision software is installed in Nuvo-9000 for implementing analysis and enabling automatic control of the whole system.

By the side of the Nuvo-9000 fanless computer is a Neousys PB-9250J-SA power backup module with patented CAP energy management technology ensuring stable and reliable power supply, extended operation hours and safe shutdown.