General overview

Mining vehicles play an important role in today’s mining operations in terms of productivity and efficiency. Fast forward to today, the application of edge AI technology allows for autonomous mining vehicles and its effects are threefold: (1) Safety, to remove human error from the equation; (2) Reduce operation cost, whether it is maintenance or labor cost; and (3) increase efficiency by introducing autonomous machines that can work 24/ 7 that does not fatigue.

Mining vehicles play an important role in today’s mining operations in terms of productivity and efficiency. Fast forward to today, the application of edge AI technology allows for autonomous mining vehicles and its effects are threefold: (1) Safety, to remove human error from the equation; (2) Reduce operation cost, whether it is maintenance or labor cost; and (3) increase efficiency by introducing autonomous machines that can work 24/ 7 that does not fatigue.

Whether it is minor lapses or repetitive workloads that wear out the human concentration, implementing AI inference technology can eliminate all, if not most human errors. But in some industrial applications, such as autonomous mining truck has other additional benefits such as putting workers out of harm’s way and into a control room where one can still oversee all the tasks he would otherwise perform while operating the truck in person.

Problem-solving

Handling heavy machinery is never a simple task and to control one situated hundred meters or kilometers away makes it that much tougher as you are unable to see the actual work environment with your own eyes. Also, finding a controller that offers rugged industrial reliability with machine vision, AI inference processing power for autonomous functions and the means to effectively and efficiently control a boom/ arm movement is not easy. Not to mention, the mining site is often in a rural or desert area exposed under the blazing sun where the machines need to operate under temperatures that can reach over 50°C.

Problem-solved

Mining vehicles follow specific routes (safety)

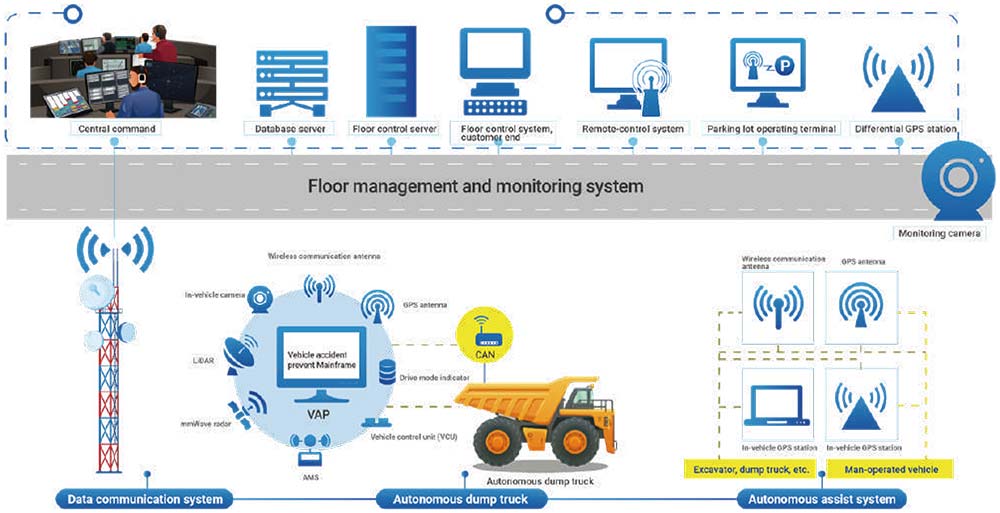

For mining sites to be safe, removing human labor from the equation is an effective way to do so. While for the operation to be 100% autonomy is not possible, but just the mining vehicles, it is possible. The autonomous mining trucks can travel between sites employing mid-way checkpoints or by GPS guidance. The Lidars and sensors onboard will detect any obstacle along the way to stop, avoid, go-around or when necessary, hand the “driving task” back to a driver who can manually drive the truck from a remote location.

Autonomous mining fleet management (reduce operation cost)

Whether it is operator salary, vehicle maintenance and consumable material costs, studies have shown the more percentage of autonomy your mining truck fleet becomes, the more the savings over time. While the obvious savings from the graph below shows “Annual Operator Salary” when in fact there are other benefits that are not shown in detail.

One example is vehicle maintenance, the Neousys computer coupled with sensors can perform predictive maintenance to help pick up small issues before they become big problems. This reduces huge repair costs and minimizes operation downtime.

Another example that was significant in studies was the fuel economy, wear of the tire tread and brake pads. As the autonomous mining trucks are GPS/ check station guided, vehicles operating in the cycle are kept at a speed where they can be constantly moving by avoiding full stops, heavy braking and hard acceleration. This puts less strain on the tire tread, brakes and at the same time, improves fuel economy.

Efficient 24/7 operation and predictive maintenance (increase efficiency)

The more autonomous trucks you have in a fleet, the more autonomy your fleet can operate. By removing human fatigue factors, autonomous trucks are capable of operating 24/7 all year round. The Neousys computers on each vehicle can also perform predictive maintenance tasks by installing sensors to pick up the slightest machine operation deviations. This means you can target the machine’s small problems before it fails and causes major downtime to your operation.

Overall, the autonomous operation can be monitored from a remote central command location, vehicles can be guided utilizing a GPS network or check-point stations in between, and requires only minimum human intervention and monitoring. This dramatically boosts mining productivity, efficiency and offers an extremely safe environment for workers.

Benefits of Neousys GPU/In-vehicle Computers

Neousys extreme-rugged edge AI GPU platforms offer the following advantages:

Environmental

- IP67 water/ dustproof GPU computer

- Extreme rugged computers for extra volatile environmental conditions

- Shock and vibration proof for in-vehicle use

- True -25°C up to 70°C wide-temperature operations for harsh, volatile environments

- Patented Cassette design for segregating thermal/ electrical interference

- Tri-axis tested patented damping bracket to withstand shock and vibration conditions

- Ultra-compact VTC systems to fit into tight spaces

Connectivity/ expandability

- PoE+ connectivity for GigE cameras

- USB3.1 Gen1/ Gen2 connectivity for USB cameras

- Connection ports with screw-lock for rugged connectivity

- WiFi 6/ WiFi 5/ 5G/ 4G wireless communication, expansion via mini-PCIe module

Inference processing power

- Support up to dual NVIDIA® RTX 30/20 series graphics cards

- Support up to NVIDIA® RTX 30/20 series graphics card

- Support up to NVIDIA® Tesla/ Quadro inference accelerators

Electrical

- Patented SuperCAP UPS to counteract unforeseen power interruptions

- Wide-range DC input

- Configurable intelligent ignition power control