Overview

The system allows growers to define orchard plots and integrate historical data through a web application to perform a precision orchard-management service designed to optimize thinning operations. During peak flowering, a tractor, mounted with an industrial computer and acquisition units such as cameras, captures images of each tree as the tractor passes. These images are processed in real time to estimate flowering intensity per tree and are geo-referenced with GPS data. Once processed, the information is uploaded to the central computer, where it generates detailed flowering maps and modulation files. These outputs enable growers to apply variable-rate treatments, such as chemical thinning, in targeted areas in an efficient manner. The approach reduces input costs, improves consistency, and enhances yield by ensuring optimal fruit load balance.

At the heart of this process is the industrial computer housed within the acquisition unit, on the tractor. This ruggedized edge device performs several critical tasks: capturing and analyzing high-volume image data, classifying flower density, and linking results with precise geo-location positioning. By processing data directly in the field, it eliminates delays and ensures actionable insights are available immediately. The computer also manages communications, transmitting the refined data to the web application for further analysis and decision support.

Challenges

Because it operates in outdoor agricultural conditions, deploying an industrial computer into a tractor-mounted acquisition unit, the system requires industrial-grade durability to withstand vibration, dust, temperature fluctuations, and power variations.

One of the key issues is environmental durability. The system must withstand constant exposure to dust, moisture, mud, and agricultural chemicals, which can compromise electronics if not properly sealed. Additionally, tractors operate outdoors under varying weather conditions, so the computer must function reliably across wide temperature ranges, from hot summer days to cold mornings.

Vibration and shock resistance are another critical challenge. Tractors often travel across uneven terrain, creating continuous vibrations and sudden jolts that could damage sensitive components or disrupt data processing. The computer must therefore be ruggedized with reinforced connectors, solid-state storage, and shock-absorbing design features.

Power stability is also a concern. Tractor electrical systems can introduce voltage fluctuations, spikes, or interruptions, so the industrial computer must integrate wide-range power input and protection mechanisms to ensure uninterrupted operation.

Finally, the unit must deliver high-performance edge processing despite the above mentioned limitations. It must capture, analyze, and classify large volumes of image data in real time without relying on cloud connectivity, which may not be accessible in rural areas. Achieving this balance between processing power and energy efficiency in a compact, rugged form factor is a significant challenge.

Solution

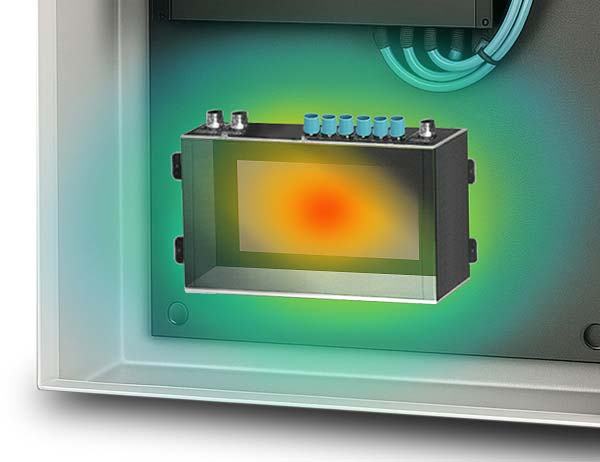

Neousys' flattop industrial computer is an ideal fit for tractor-mounted acquisition units in precision agriculture applications. Its unique flattop heatsink design allows the system to be mounted against the inner wall of a sealed cabinet, using the enclosure itself as an extended heat spreader. This approach not only improves heat dissipation under heavy computational loads, such as real-time image analysis, but also ensures reliable performance in confined, fanless environments where airflow is limited. By transferring heat directly to the cabinet, the design reduces thermal buildup and extends the component's lifespan, a critical factor for systems operating continuously in the field.

The flattop form factor also reduces overall system height, making the computer easier to install in tight spaces commonly found in tractor enclosures. Beyond thermal efficiency, the system is engineered for rugged outdoor deployment, with wide operating temperature tolerance and MIL-STD vibration and shock resistance to handle bumpy terrain and harsh agricultural conditions. Its wide-range DC power input with ignition control allows smooth integration into tractor electrical systems, while rich I/Os including GMSL2, PoE+ Ethernet, USB with locking connectors, and expansion slots to ensure seamless connection with cameras, GPS, and wireless communication modules.

By combining compact design, efficient heat dissipation, and rugged reliability, Neousys' flattop computer provides the robust edge processing backbone needed to capture, process, and transmit real-time orchard data. It ensures consistent performance in environments where conventional fan-cooled computers would struggle, making it the perfect embedded solution for agricultural acquisition systems.

Product Highlights

NRU-161V-FT

Flattop Heatsink Edge AI Computer

- Powered by NVIDIA® Jetson Orin™ NX or Orin™ Nano

- Supports 6x GMSL2 automotive cameras with pre-built drivers

- 199×136×49 mm low-profile design with flattop heatsink

NRU-162S-FT

Flattop Heatsink Edge AI Computer

- Powered by NVIDIA® Jetson Orin™ NX or Orin™ Nano

- Supports 4x PoE+ GbE via M12 X-coded connectors

- 199×136×49 mm low-profile design with flattop heatsink