Overview

The first conveyor belt was invented back in 1905 by Richard Sutcliffe and it changed the coal mining industry. In 1913, Henry Ford (Ford Motor) came up with the first conveyor belt assembly at their Michigan factory, and that kicked off factory automation in the years to come.

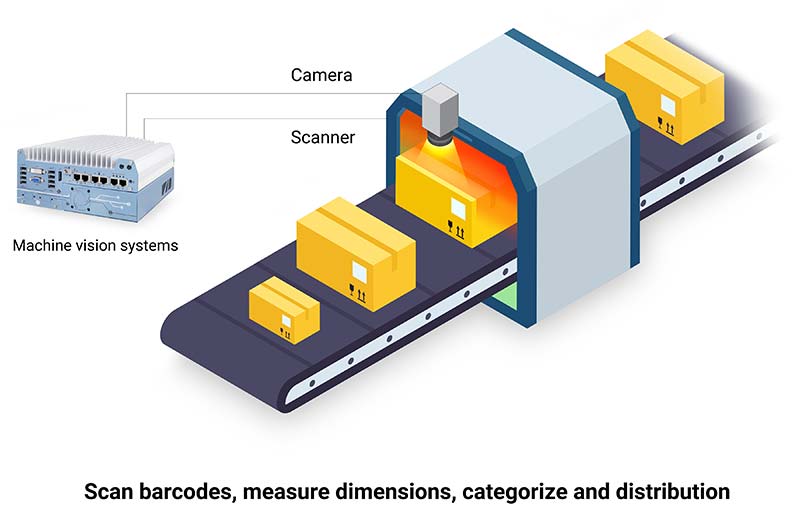

Nowadays, machine vision systems are essential machinery in logistics distribution centers/ hubs as they offer extreme efficiency in quantitative structured and systematic processes whereas man-power vision excels in qualitative non-structured/ non-systematic inspections. The machine vision systems also offer system integrators to design customized conveyor belt and sorting systems. They save man-power, space and offer efficiency by scanning products and barcodes (registering the item on the system) while the conveyor system moves things along in a steady and orderly manner.

In summary, a reliable customized reliable machine vision system, conveyor and sorting system offer safety, cost savings, reduce downtime, quality and quantity automation process benefits.

One of our customers implemented a machine vision system that scanned parcels from superior and lateral positions. The scanning method allowed the machine vision system to scan for barcodes and at the same time, integrate the sorting process by their size as it measures the height, width and depth of the parcel. Then based on the parcel dimensions (size), the conveyor belt sends each parcel into designated areas for parcels their size.

The customer chose to utilize a Neousys Technology’s Nuvo rugged embedded series wide-temperature system as the controller system to their machine vision scanner distribution system. The system performed effectively and parcels were scanned and distributed with consistency and precision. The main demand on the controller system was its ability to operate extended hours in higher-than-usual ambient temperature range as the warehouse is air-condition-less, not well ventilated and items are placed within close proximity of each other to maximize space.

Neousys Rugged DNA

Fanless operation

The rugged and efficient heat dissipation design allows 24/7 fanless operation.

True wide temperature operation

Often praised for the system’s ability to operate in extreme temperature conditions, Neousys Technology’s rugged embedded systems feature true wide temperature operation (up to 70°C) capability.

Processing power

Neousys Technology’s Nuvo rugged embedded series supports up to 9th Gen Intel® Core™ i CPUs.

Patented MezIO™ interface

Via expansion sockets, Neousys systems can install WiFi, 4G cellular modules or both in the system. They offer wireless communication with other nearby devices, central computer or cloud systems.

Abundant connections

The embedded systems feature USB 3.1 Gen1, USB 3.1 Gen 2 (Nuvo-7000 series), GbE, PoE, COM, etc.

Wireless communication module

Via expansion sockets, Neousys systems can install WiFi, 4G cellular modules or both in the system. They offer wireless communication with other nearby devices, central computer or cloud systems.