"Is it faulty when a fanless industrial PC feels hot to the touch?" In general, we're used to the slight warmth of a laptop or home PC, so when we touch the heatsink of a fanless industrial PC in operation, our immediate concern is whether it's overheating or malfunctioning.

In fact, the hot to touch heatsink does not mean it is malfunctioning but rather that the fanless industrial PC's passive thermal design is working. To operate stably for long periods in harsh environments, fanless industrial PCs have a completely different thermal philosophy than home PCs. Thermal design is the key to ensuring system reliability. This article will delve into why fanless industrial PCs "feel hot to the touch" and reveal the thermal management technologies behind them.

Fanless Industrial PC vs. Home PC: The Main Difference in Thermal Design Home PC: Active Cooling

- Uses fans to draw heat away from hot components like the CPU and GPU

- Pros: High cooling efficiency.

- Cons: Fans cannot operate in dusty, high-temperature, humid, or high-vibration industrial environments, as they may accumulate dust and result in damage or failure, leading to system overheating and shutdown.

Fanless Industrial PC: Fanless Passive Cooling

- Relies on thermal materials, aluminum enclosure, heatsink fins, and heat pipes to conduct heat to the surface for dissipation.

- Pros: Completely eliminates fans (point-of-failure), to offer high stability, maintenance-free, dust- and vibration-resistant, and extend lifespan.

- Cons: The surface temperature of the heatsink/ enclosure is higher and may feel "hot" to the touch.

Why Does a Passively Cooled Heatsink Get Hot?

In electronics, heat is the number one threat to component lifespan. High temperatures accelerate the aging of electronic parts, loosen solder joints, and even compromise data integrity.

The cooling principle employed by fanless industrial PCs is to conduct the heat generated by components to the outer surface of the heatsink/ enclosure, which the heat can then dissipate. Therefore, if a fanless industrial PC's heatsink/ enclosure is hot to the touch, it actually means it has effectively drawn heat away from critical components, ensuring system stability.

Three Common Passive Cooling Technologies in Fanless Industrial PCs

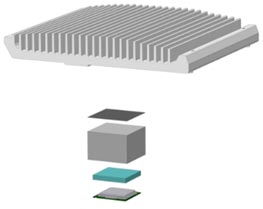

1. High-Efficiency Thermal Materials

- Industrial-grade thermal paste and thermal pads fill tiny gaps between the CPU/GPU and the heatsink.

- Long-lasting and resistant to degradation, they ensure stable cooling efficiency even under long-term high-temperature operation.

2. Aluminum Enclosure with Heatsink Fins

- The full aluminum enclosure itself acts as a large heatsink.

- Special fin structures increase the surface area to rapidly dissipate heat.

3. Heat Pipe Technology

- Used in high-performance or space-constrained models.

- Utilizes the principle of phase change to quickly transfer heat away from the heat source, significantly boosting cooling efficiency.

Neousys Technology's Fanless Thermal Design

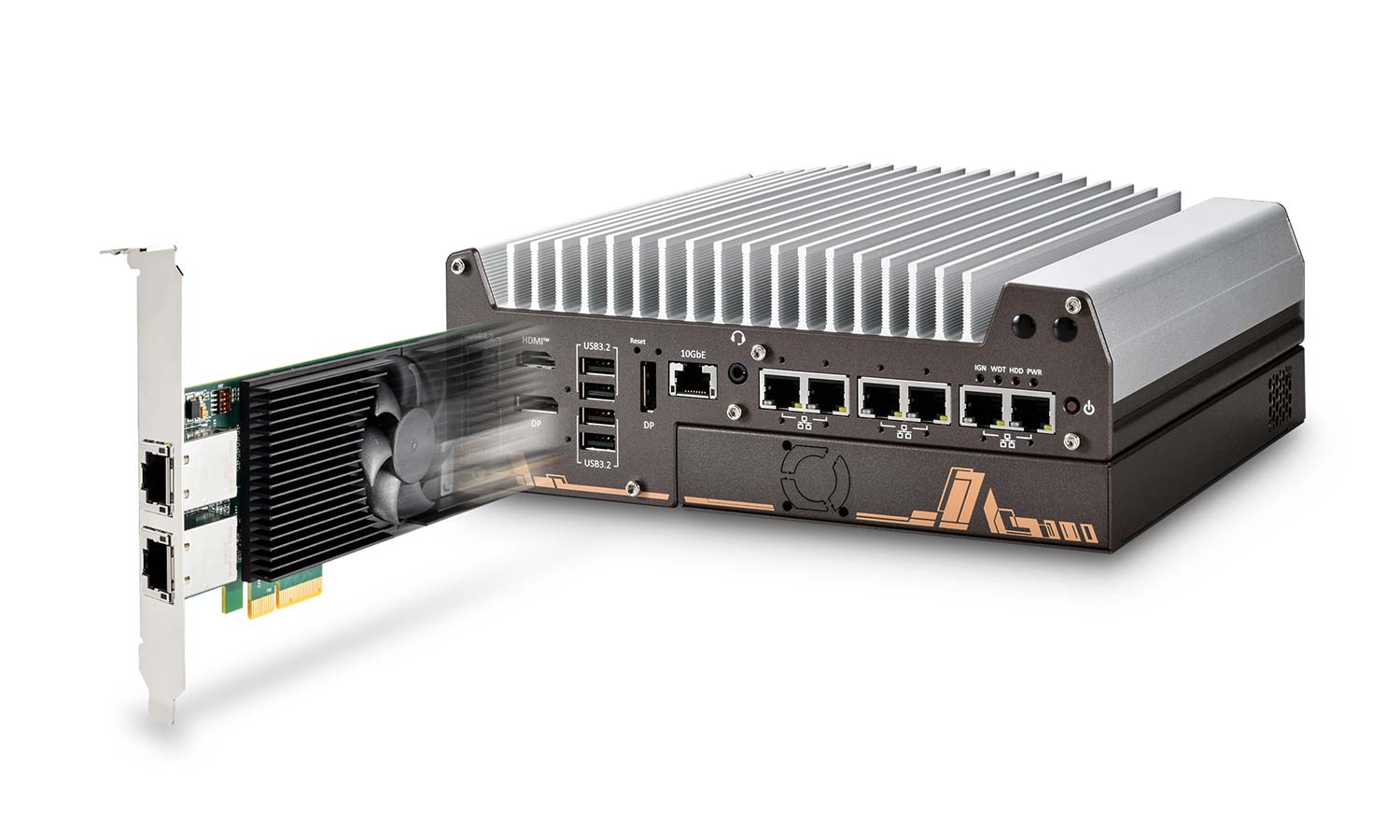

In response to harsh industrial environments, Neousys fanless industrial PCs’ thermal design utilizes aluminum casing + heatsink fins + thermal materials. The layout is optimized at the mainboard design stage to evenly distribute hot components across the PCB to help achieve heat-soak equilibrium.

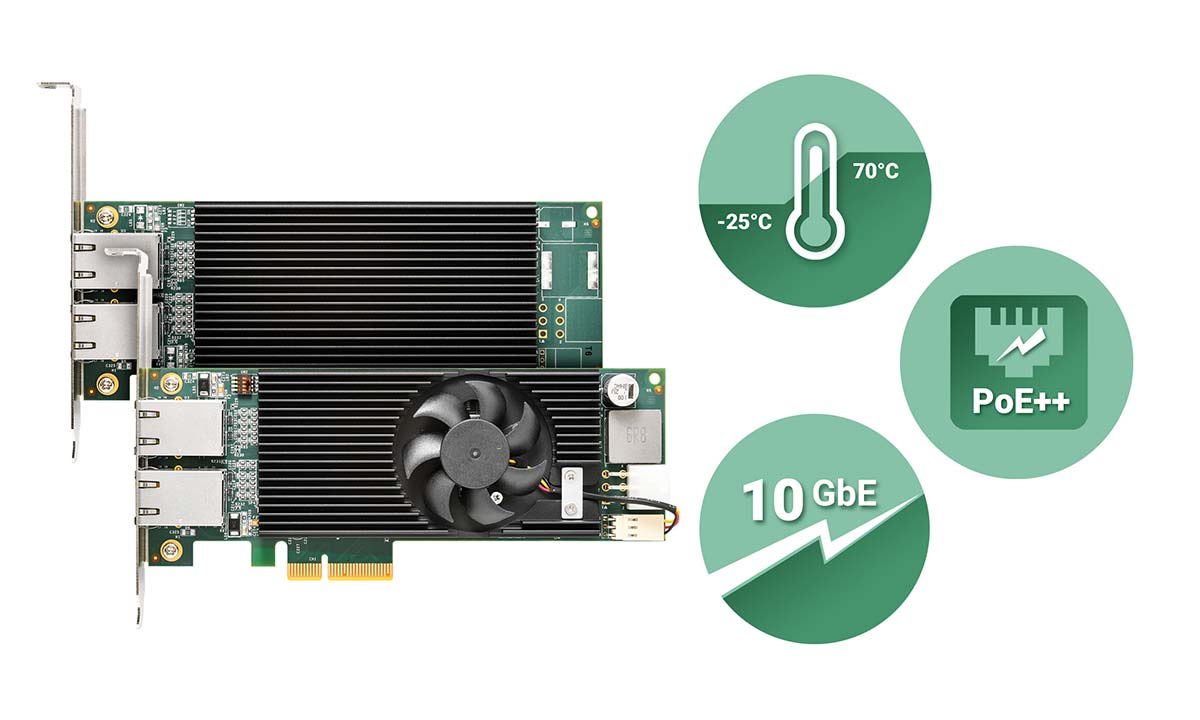

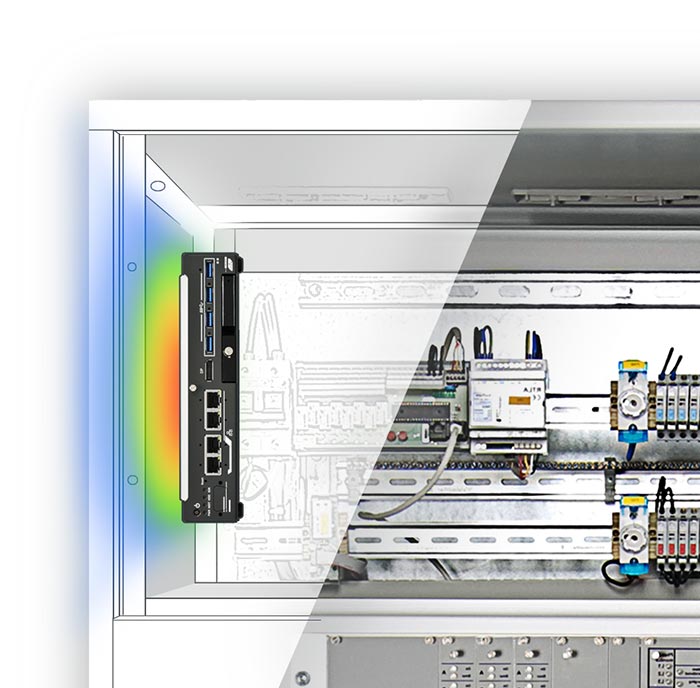

Based on test data, at an ambient temperature of 70°C, the aluminum heatsink can reached a maximum surface temperature of 88.8°C with infrared thermography showing uniform temperature distribution across the heatsink, suggesting the strategic placement of components effectively avoided heat-soaking in concentrated areas.

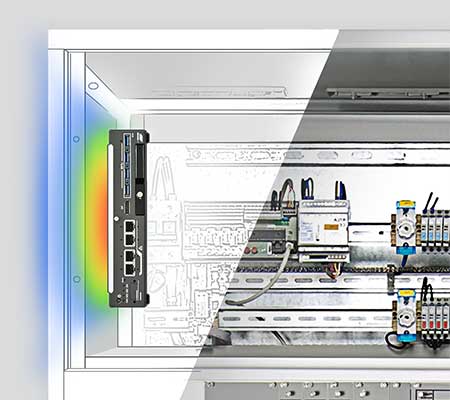

For installation within enclosures, Neousys' fanless flattop computers, FT series, their heatsink is mounted directly onto the enclosure wall surface with a thermal pad, conducting heat onto the outside of the enclosure. This design serves two purposes, one, it prevents heat buildup inside the enclosure, and two, without the heatsink fins, the system is smaller in dimensions, making it ideal for confined or enclosed systems.

Conclusion: Hot to the Touch Means Heat Conducted to Heatsink

When your fanless industrial PC feels hot, it means heat generated by components are being conducted onto the surface of the heatsink. It is protecting itself, ensuring stable long-term operations in harsh environments.

From advanced thermal interface materials and aluminum fins to heat pipe technology, these thermal designs are engineered to sustain fanless industrial PC high-performance and longevity of fanless industrial PCs, even under harsh environmental conditions.

Frequently Asked Questions (FAQ)

- Is it normal for a fanless industrial PC to feel hot to the touch?

Yes, it is. Fanless industrial PCs use a fanless passive cooling design that conducts the component generated heat to the heatsink/ enclosure. Therefore, a higher surface temperature is normal. - Why don't fanless industrial PCs use fans for cooling?

Industrial environments often have dust, high temperatures, moisture, and vibrations. Fans are prone to accumulating dust or damaged, leading to overheating. A fanless design avoids this point-of-failure by utilizing thermal materials, aluminum casing, heatsink fins, and heat pipes for passive cooling. - What is a normal heatsink/ enclosure temperature for a fanless industrial PC?

Depending on the environment and workload, the surface temperature of a fanless industrial PC's aluminum casing is typically between 50°C and 90°C. Even if the heatsink/ enclosure feels hot to the touch, as long as it operates within the specified temperature range, it's considered normal.

- Learn more about Neousys Flattop Heatsink Fanless Computer: https://www.neousys-tech.com/en/product/product-lines/industrial-computers

- Learn more about Neousys Industrial Rugged Computer: https://www.neousys-tech.com/en/product/feature/flattop-heatsink-fanless-pc