Overview

Autonomous technology is being applied to previous human-operated machinery and trains are no exception. By integrating AI/ML inference capabilities with cameras and sensors into trains, it allows trains to see, reason, and decisions based on what was perceived.

With the implementation of autonomy, railways are transformed and can solve railway industry’s pain points and helps infrastructure engineers, train operators and public transport authorities to better manage railways. Here’s how the autonomy technology can help transform modern railways in several ways:

- Carry more load/ passengers per trip - Without the need for locomotive personnel onboard, the few carriages of living quarters can be turned into standard carriage compartments.

- Reduced energy consumption - The ability to carry more each trip means less trips need to be made and less fuel/ energy consumed in the long run.

- Centralized coordination for punctuality - Centralized management meant the trains themselves know when and how to recover from disruptions to ensure schedule punctuality.

- Mitigate communications-based train control (CBTC) system deployment - A railway signaling system using telecommunication between train and track equipment for a safer and efficient traffic management and control. It also offers faster deployment of CBTC as conventional CBTC, positioning is determined using wheel odometers and tag readers under the train. Autonomous positioning solves these problems and delivers new benefits. Autonomous positioning integrates seamlessly with CBTC, requires no wayside equipment and the entire onboard system can be fitted in as little as two days – with no need to work under the train.

- Serving rural railways - Rural and extended railway branches are often under-served, this holds true for almost all countries. Autonomous trains offer minimum operating costs and maximize carrying capacity.

- Predictive maintenance - The autonomous system can also incorporate predictive maintenance components/ systems to target minor issues before they become costly repairs. This would also minimize overall downtime and offer better safety.

- Real-time monitoring of surrounding infrastructure - The edge AI computer system on autonomous trains are capable of gathering data about their surroundings, including cuttings, embankments, lineside infrastructure, buildings and vegetation, such as trees. This can be used to create a topographic database – and to establish a baseline of normality against which deviations can be measured in real time. This can be further refined by integrating external data, such as weather reports. This has immense value in applications which range from detecting the risk of slip-slide during the leaf-fall season, to monitoring changes in the condition of earthworks beside the track.

Challenges

Electronic equipment deployment on rolling stock has always been problematic due to the operating environment equipment must endure. It must sustain operations under constant vibration, heat, tight installation space, electrical supply issues, etc.

In addition to the environmental conditions, the electrical challenge proves to most challenging. Due to a short circuit on a DC supply distribution line and subsequent operation of fuse/circuit breakers, input voltage may suddenly be reduced to 0V for a fraction of a second, which is defined in the EN 50155 standard. EN 50155 is the European standard for railway electrical equipment and it is the standard most countries will refer to.

One of the definitions of EN 50155 standard is that the normal input voltage must comply to 0.7 to 1.25 times the steady-state (continuous) voltage; and comply to 0.6 to 1.4 times the fluctuation voltage range for a fraction of a second. Please refer to the table below:

| Normal Input voltage (V) | Steady-state (continuous) voltage range (0.7*V – 1.25*V) | Fluctuation voltage range 0.6*V (0.1s) – 1.4*V (0.1s) |

| 24 | 16.8 - 30 | 14.4 – 33.6 |

Third Rail System

Third Rail System

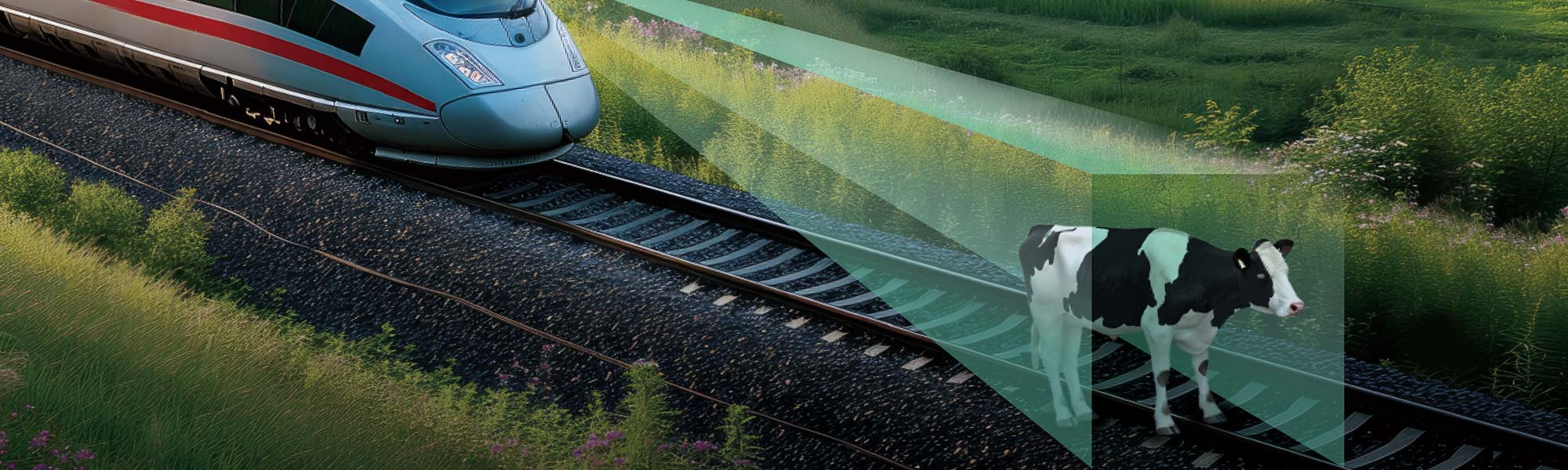

Object Detection

Object Detection

Another point of failure in the rolling stock’s electrical system is the "Third Rail System" or the "Conductor Rail System". One of the disadvantages of the Third Rail system is the gaps in the conductor rail at level crossings and junctions where the train is in a position with no electrical power. Hence the minimum length of trains required to be able to push the "gapped" train’s contact shoes back onto the live rail. The gaps lack the third rail conduct and hence no electricity will be delivered.

The computer on the autonomous train needs to be able to detect objects on the rail track and bring the train to a standstill. It must also provide enough processing power for other tasks such as onboard passenger monitoring, or possibly rolling stock predictive maintenance monitoring.

Solution

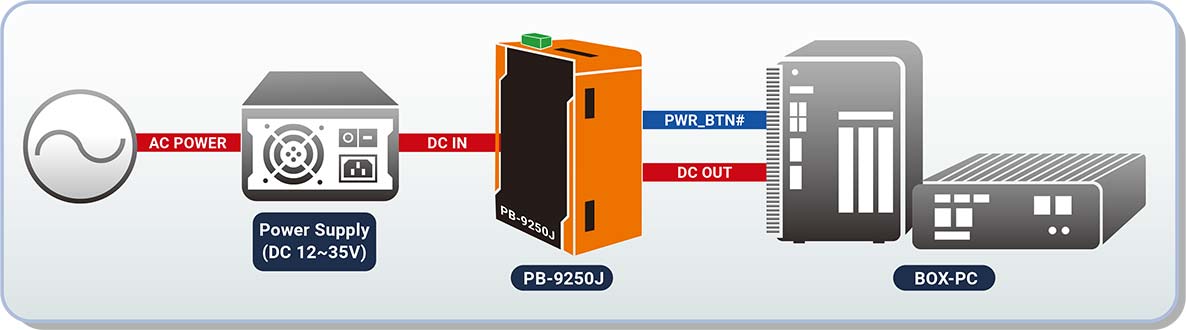

The customer chose to implement a Neousys rugged embedded GPU computer Nuvo GC series for its ability to incorporate a GPU for AI-inference and when coupled with a PB series SuperCAP power backup module to supply temporary operating electrical power supply.

The edge AI inference ability is dependent on the GPU card installed and the Nuvo GC can support up to dual NVIDIA RTX 40 series GPU cards.

To counter the sudden loss or instability of electricity on trains, a PB SuperCAP power backup module can be incorporated for Nuvo GC to supply up to 9250 watt second of power. It can sustain the system through the safe shutdown process, protect the hardware and data. It also comes with a damping bracket that is compatible with MIL-STD-810G and withstand up to 3Grms so it can operate without a glitch on trains.

The system also features true wide temperature operation capabilities. The system can accept a wireless module (WiFi or 5G/ 4G) for realtime video/ data upload or training program download.

One of the main reasons the Nuvo GC series was implemented for the analytics system was due to its wide-range operation temperature. With the system positioned on the field, directly under the sunlight, the temperature can soar quickly that may cause system performance throttling, shutdown, or permanent damage. The Neousys Nuvo platform offers AI video analytic ability, and solution to power consumption, resistance to shock and vibration, true wide-temperature operation, connectivity, wireless communication, etc., making it the perfect platform for the AI-enabled analytic system.