Overview

Tens of thousands of roads can be found in major cities around the globe. The intertwining network of roads is vital to any major city’s infrastructure as it may impact the economy and everyday living. A well designed road network contains traffic lights, stop signs, consideration of traffic flow, area population density, etc. to ensure free-flowing traffic throughout. But roads are man-made and are subject to tremendous wear and tear from vehicles tires, the harsh sun, and pouring rain, defects and damages often become dangerous hazards.

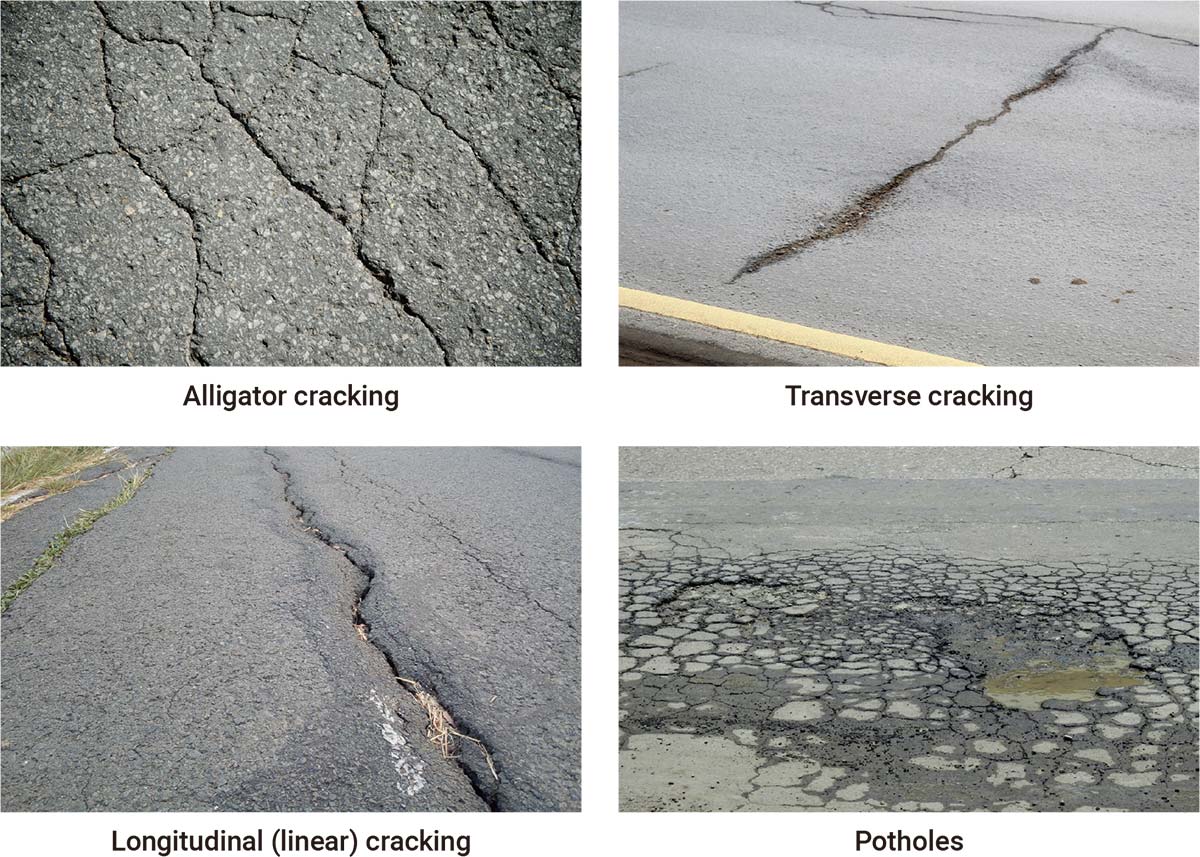

To categorize, there are 13 types of defects/ damages (refer to the Appendix section for details)

- Oil spots

- Grass

- Mud, tree sap, etc.

Challenges

To inspect and detect faults on the road require significant manpower, equipment, work hours and budget. Not to mention some damages on the road may require immediate attention to avoid accidents and injuries. Hence the development of intelligent road inspection utilizing a standardized pavement management system (PMS), it provides a systematic method of road condition data collection, storage, analysis and modelling for decision-making associated with optimising resources across a pavement network.

Usual components of an intelligent road inspection PMS include:

At the network level, a PMS facilitates decision-making for long-term ‘needs based’ budgeting to address the overall condition of the network. At the project level, a PMS addresses the most cost effective maintenance and rehabilitation means for each road segment. Achieving the desired performance outcomes has a significant impact on both the timing and type of treatment chosen.

However, to implement an AI-based detection in a vehicle, it must conqeuer environment conditions, time for software development to recognize defects, and detection accuracy

Environment

Environment for computers installation

- Outdoor

Wide temp. & dust/ dusty environment

- Mobile

- Shock/ vibration endurance

- Ignition & LTE support

- Limited space

Wide temp. & dust/ dusty environment

- Shock/ vibration endurance

- Ignition & LTE support

- Limited space

Time

Time consuming for program development of multiple road damage recognition

Result

Not able to retrieve the inspection with accurate and object result

- Edge inference with self-learning model and decision making

Solution

The intelligent road inspection removes human factors such as inconsistency and fatigue out of the inspection equation by installing an AI inference computer. The AI inference computer detects and determines defects based on the same knowledge database, making the results more consistent; detected defects that require immediate attention can be sent back to central control through wireless 5G/ 4G communication; the ability to simultaneous deploy multiple vehicles means more roads and wider areas can be covered.

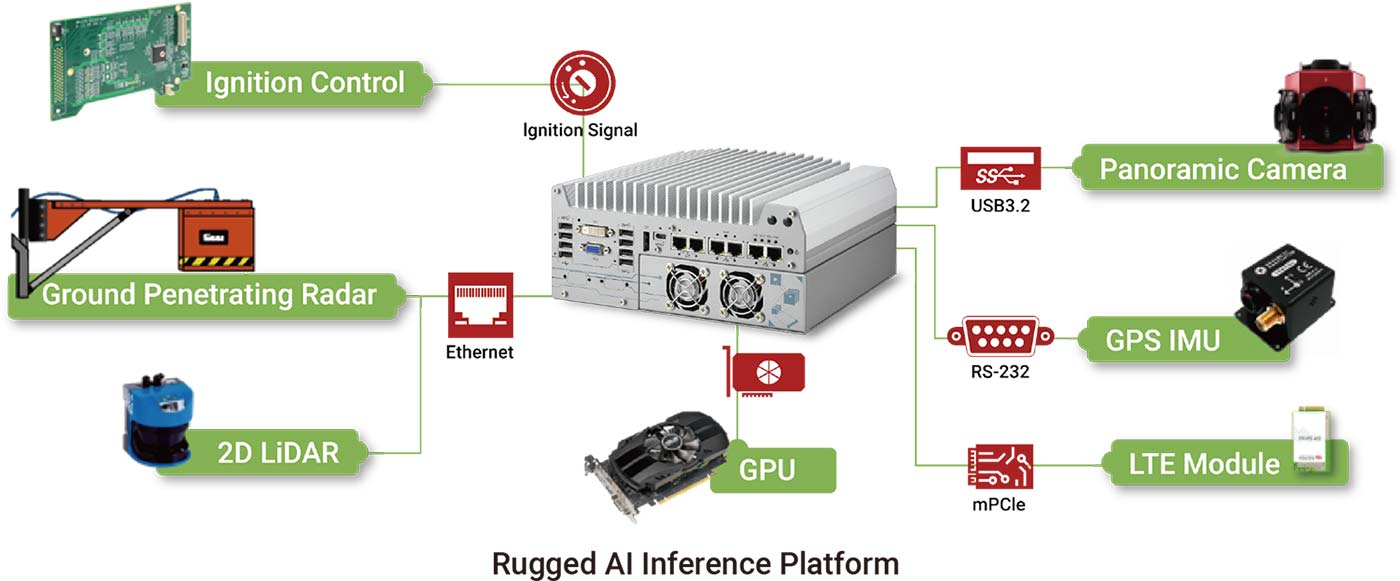

Our customer chose to implement a Neousys rugged AI inference platform, the GC series into the intelligent inspection vehicle. The system features true wide temperature operation and has an assortment of connectivity allowing for PoE, USB or GigE cameras connections in detecting cracks and abnormalities on the road; the 120W NVIDIA GTX graphics card brings AI inference capability to determine the type and severity of the damage; with built-in ignition control, MIL-STD-810G shock and vibration certification, the system is built for the tough conditions of in-vehicle deployment.

The advantages of implementing an intelligent road inspection vehicle improved the inspection consistency and recognition of pavement damages. The computer references from an ever increasing database of pavement images collected from other intelligent road inspection vechicles, and learns from it. The process also saved manual labor inspection time and early detection means taking care of small problems before they become big issues.

Accurate prediction of road conditions at an earlier stage

Reduce manual road inspection time from weeks to seconds

Improving quality inspection consistency and results

Increase safety for both road inspectors, road maintenance workers and the traffic surrounding them

Outcomes:

On top of solving in-vehicle and environmental conditions, the Neousy GC series computers feature expansion slots to accommodate 5G/ 4G wireless communication and GPS modules. The 5G/ 4G communication module allows for data upload, live image feedback or communications in general; while the GPS module allows the intelligent road inspection vehicle to be tracked wherever it may be or deployed to the ruralest of places, if need be.

Integrating the power of an inference accelerator, efficient and effective thermal dissipation, shock and vibration resistance, abundance of connectivity for cameras, Lidars, sensors and the ability to expand functions, it is no wonder why our customers chose a Neousys GC series computer to be at the helm of their intelligent road inspection vehicle

Benefits of Neousys Rugged Embedded GC Series Computers

Neousys rugged embedded GC series platforms offer the following advantages

- True -25°C up to 60°C wide-temperature operations for harsh, volatile environments

- Patented damping bracket to withstand shock and vibration conditions

Connectivity/ expandability

- PoE+ connectivity for GigE cameras

- USB3.2 Gen1/ Gen2 connectivity for USB cameras

- Connection ports with screw-lock for rugged connectivity

- WiFi 6/ WiFi 5/ 5G/ 4G wireless communication, expansion via mini-PCIe/ M.2 modules

Inference processing power

- Supports an NVIDIA® graphics card up to 130W

- Supports an NVIDIA® Tesla/ Quadro/ L4 inference accelerators

- Patented SuperCAP UPS to counteract unforeseen power interruptions

- Wide-range DC input

Expansion

- MezIO ignition control

- MezIO digital input/ output, COM, Ethernet, USB