Overview

Pantograph maintenance has been a long-standing issue for electric trains, as this apparatus mounted on the rooftop of trains plays a critical role in establishing contact with the catenary that supplies power from the overhead line to the rolling stock. However, traditional manual inspections conducted at the depot on a regular base sometimes fail to detect faults in pantograph before they develop into a problem causing overhead wiring tear-downs and resulting in lengthy network delays, costly recovery, and serious safety concerns.Therefore, rail network operators and infrastructure owners are looking into technologies that can monitor pantographs in real-time and respond to problems in advance.

Pantograph maintenance has been a long-standing issue for electric trains, as this apparatus mounted on the rooftop of trains plays a critical role in establishing contact with the catenary that supplies power from the overhead line to the rolling stock. However, traditional manual inspections conducted at the depot on a regular base sometimes fail to detect faults in pantograph before they develop into a problem causing overhead wiring tear-downs and resulting in lengthy network delays, costly recovery, and serious safety concerns.Therefore, rail network operators and infrastructure owners are looking into technologies that can monitor pantographs in real-time and respond to problems in advance.

A European intelligent monitoring solution provider has designed the world’s first Pantograph Condition Monitoring System (PCMS) based on stereo vision technology and artificial intelligence to improve operational decision-making on train monitoring. Their solution is a wayside system that deploys inspection point (s) along the rail route to take images of the pantographs passing through the inspection site. It analyzes the health condition of the pantograph based on processed images, and releases alarms and notifications should any monitored parameter(s)reach the set threshold so countermeasures can be taken in time and avoid teardowns.

Data will be uploaded to the cloud in real-time for access by competent persons, and for big data analysis on pantograph wear trends (for example, history of changes in carbon strips are important indicators for wear degree and longevity of the pantographs), so that predictive and preemptive maintenance can be implemented. Regular depot inspections could be taken perhaps only once every 10 weeks for each train; while the wayside real-time monitoring system may implement checks of a train several times in a journey without withdrawing the train from service.

This automated real-time monitoring system reduces the need for the maintainers to access the top of the carriage for manual inspections, providing them a safer working environment and a tool for optimizing maintenance schedules. For the overall network operations, it helps to reduce risks to infrastructure, improve operational efficiency, maximize the availability of rolling stock fleets, and drives the railway to a digital and sustainable future.

Challenges

Superb ruggedness for outdoor application in railway environments

Such wayside monitoring systems have to endure weather conditions in the outdoor environment,which is subject to shock and vibration caused by passing trains and electromagnetic interference from the high-voltage infrastructure. Rugged designs to mitigate these negative factors are mandatory for the embedded system to ensure stable and reliable day-to-day operations.

Demanding performance for image processing and AI computing

Given the extreme conditions in railway environments, the system must have a commensurate processing power for processing 3D imaging and running AI analytics, imposing greater challenges for computer designers in tackling heat dissipation and other reliability issues.

Solution

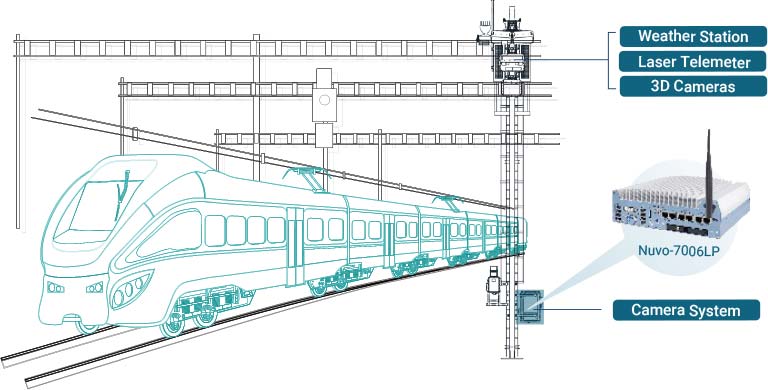

This 3D pantograph monitoring system is composed of: a weather station that collects weather data to be utilized in advanced wear algorithms; a laser telemeter emitting low-power laser beams for detecting the position, speed, and direction of passing train; and an advanced camera system for capturing right/left close-ups of the monitored pantograph and reading carriage ID linked to the pantograph.

At the heart of the system is Neousys’ embedded computer Nuvo-7000 series, which provides I/O links to all system components for fetching monitoring data, merges the left and right images of the pantograph from stereoscopic cameras into an accurate 3D model, and implements machine learning algorithms to assess pantograph condition against predefined criteria.

Advantages of Neousys Nuvo-7006LP

A superb rugged embedded system designed for applications in harsh outdoor environments, the Nuvo-7000 series provides wide-temperature operation from -25°C to 70°C, is certified to US military standards for shock and vibration (operating, MIL-STD-810G) and CE/FCC Class A for EMC capability.

A high-performance edge AI computer providing satisfactory graphic processing power, high capacity storage and high-speed data throughput for 3D image processing, and commensurate computing power for running machine-learning analytics with an ideal performance/cost ratio.

Diverse and flexible I/O configuration satisfies connectivity to system components including stereo cameras, communicating with the weather station, and allows for application expansion via add-on cards.