General overview

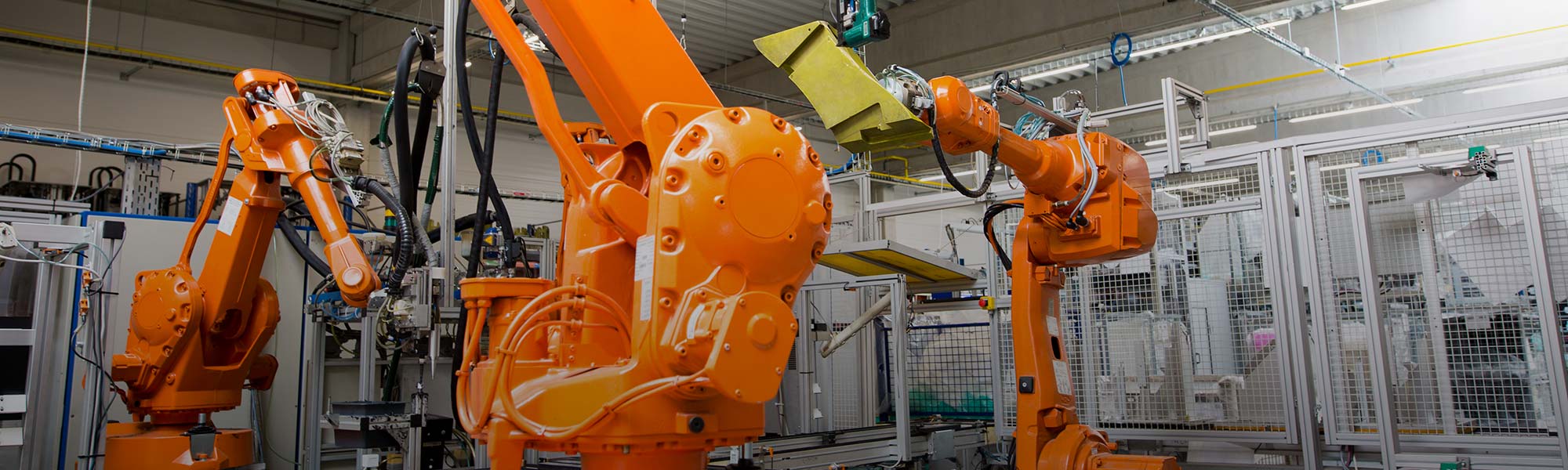

Robotics and machine vision are common automation applications in smart factories. The robotics system can detect and pick out machine tools and place them into storage, awaiting maintenance or restoration. With the development of Industry 4.0, building a smart factory requires intelligent robots, industrial gateways, etc. to maintain quality, consistency and manufacturing efficiency.

Collecting real-time data, an IoT gateway is positioned at the edge between devices/ sensors and cloud applications/ systems.

The industrial IoT gateway is no different and is implemented to acquire real-time operational statuses via industrial-specific data acquisition channels and analytically present valuable operation insights to improve efficiency, and in the process may predict or prevent problems. Although the practical application of the industrial IoT is extremely diversified, however, the core essential elements remain the same. Of which, an industrial IoT gateway plays the role as the data gatekeeper between operational technology (OT) to information technology (IT). The industrial IoT gateway acquires data, processes local data, translates data/ communication protocols, secures data for transport, sends translated data to the cloud, and also allows data to flow back to OT devices for a probable action. To execute functions, an industrial IoT gateway must have the following capabilities: built-in industrial-specific data acquisition channels, edge computing, data wrangling, data encryption, pre-certified by wireless carriers, support for cloud communications and the ability to survive in harsh/ rugged industrial environments.

Problem-solving

DSA, the smart factory expert wanted to implement a controller into the DSA DS intelligent tool cart (DITC). It needed to be able to communicate with multiple tools (RFID), upload the acquired tool data onto the cloud server while commanding the movements of the AGV within the factory floor.

Problem solved – Neousys Technology IGT-30 Industrial IoT Gateway

Once the tool is in the storage DITC, it can be delivered for restoration via two methods; one, manually delivered by the operator and two, the intelligent cart are automated guided vehicles (AGV) that can move the tools from work station to restoration area (A to B, and vice versa). The manual delivery method is usually preferred if the particular tool is needed urgently.

With the tools being delivered, the IGT-30 IIoT gateway in the AGV collects the intelligent tool’s RFID and data using Modbus communication protocol to establish a master-slave communication infrastructure that allows for multiple tool connections and communication. The collected data is then sent by the Neousys IGT IIoT gateway using the MQTT protocol to the cloud. The unique IGT-30 gateway is capable of both communication protocols, MQTT & Modbus, without the need for converters, making the implementation and deployment that much easier.

Benefits

The Neousys Technology IGT-30 is more than just an IIoT gateway and offers the following benefits:

- It is Microsoft Azure and AWS certified meaning it can be quickly deployed and implemented with a vast amount of compatible certified devices on the IIoT market

- IIt is a full-fledge miniaturized computer that features an ARM-based PC with computing power with pre-installed Debian

- IFeatures specific data I/Os for various industrial sensors and multi-protocol communication capabilities

- IIt has common embedded connections that includes a USB2.0 port, two 10/100M LAN ports, one configurable COM port (RS-232/422/485) and an optional CAN bus port.

- IIn addition, there are also eight built-in isolated digital input channels for various sensors or buttons/ switches; and two built-in isolated digital output channels to control actuators and indicators.

Neousys True Industrial Gateway DNA

Fanless operation and efficient heat dissipation

IoT communication protocolsTCP, IP, Modbus, MQTT

In addition to accepting 12-25VDC input, IGT-30 can also operate in powered device mode by accepting power delivery from a power source device (PSD)

Neousys embedded systems and IoT gateways thrive in harsh conditions, specifically under high-temperature operation (from -25°C up to 70°C).

IGT series intelligent industrial gateways come with Debian OS pre-installed are Microsoft Azure and AWS certified.

The system is designed to withstand operating shock and vibration conditions with patented damping brackets.

Via expansion sockets, Neousys IGT series IoT gateways can install WiFi or 4G cellular modules to offer wireless communication with other nearby devices, central computer or cloud systems. The IGT series IIoT systems may also offer analog inputs (0-10V, 4-20mA), digital I/Os, CAN bus, USB, LAN, COM, etc.