HOME / Technologies / How Edge Computers Conquer Heat in Space-Limited Enclosures or Cabinets

How Edge Computers Conquer Heat in Space-Limited Enclosures or Cabinets

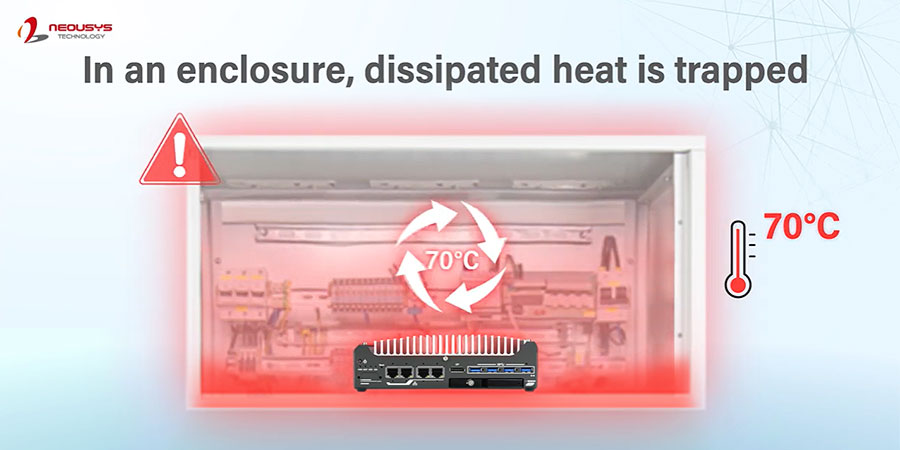

In industries such as food and beverage, chemical processing, and electronics manufacturing, computers and electronic control devices are critical for automation and inspection applications. To protect these sensitive components from harsh environments—such as exposure to liquids, chemicals, and high humidity—these devices are often housed in sealed or waterproof enclosures. While these enclosures offer excellent protection, they introduce significant thermal management challenges and also limited space issues.

When housed in a sealed enclosure, heat generated by edge computers and other electronic devices accumulates quickly. The problem becomes even more pronounced when running resource-intensive applications like AI-powered vision inspection or real-time data processing, where GPUs and CPUs generate substantial heat.

Without effective thermal management, overheating can lead to:

- Performance degradation as processors throttle to reduce heat.

- Shortened component lifespan due to prolonged exposure to high temperatures.

- System instability that may eventually lead to unplanned downtime.

To address overheating in confined enclosures, several approaches have been developed, including:

| Traditional Thermal Management Solutions | Practice | Limitationss |

| Optimizing Layout and Positioning | Carefully arranging components to improve airflow and minimize heat spots is a common strategy. | Space constraints, especially in compact enclosures, and does not eliminate heat effectively in sealed systems. |

| Adding Thermal Management Systems | External cooling solutions, such as fans, heat exchangers, or air conditioners, are widely used. | Increase complexity, cost, and maintenance needs. Impractical for waterproof or sealed enclosures, which rely on maintaining airtight integrity. |

| Using Larger Enclosures | Switching to larger cabinets allows for more heat dissipation and airflow. | Conflicts with the need to save space, particularly in industries with tight spatial constraints or mobile applications. |

| Advanced Computer Enclosure Designs | Some manufacturers design computers with built-in thermal solutions, such as passive cooling. | Insufficient for high-performance applications, limiting their usability in demanding AI-driven tasks. |

Neousys tackles these challenges with its flattop heatsink design, a cutting-edge thermal solution tailored for limited-space enclosures. It has an innovative heatsink design that attaches to the inside of the enclosure wall, and leverages the wall as a larger heat-dissipating area, eliminating the need for traditional cooling fins and ensuring reliable operation across a wide temperature range of -25°C to 60°C, even during intensive AI computations.

The Neousys in-cabinet IPC, the flattop heatsink computer can operate under 100% load without thermal throttling. Offering smaller overall dimensions and not needing to allocate clearance space for cooling (space saving), it means there is more room to place other devices in the enclosure, or one can space-out the devices for better cooling.