HOME / Applications / AI Robotic Dog Keeps Factory/ Industrial Sites in Check

AI Robotic Dog Keeps Factory/ Industrial Sites in Check

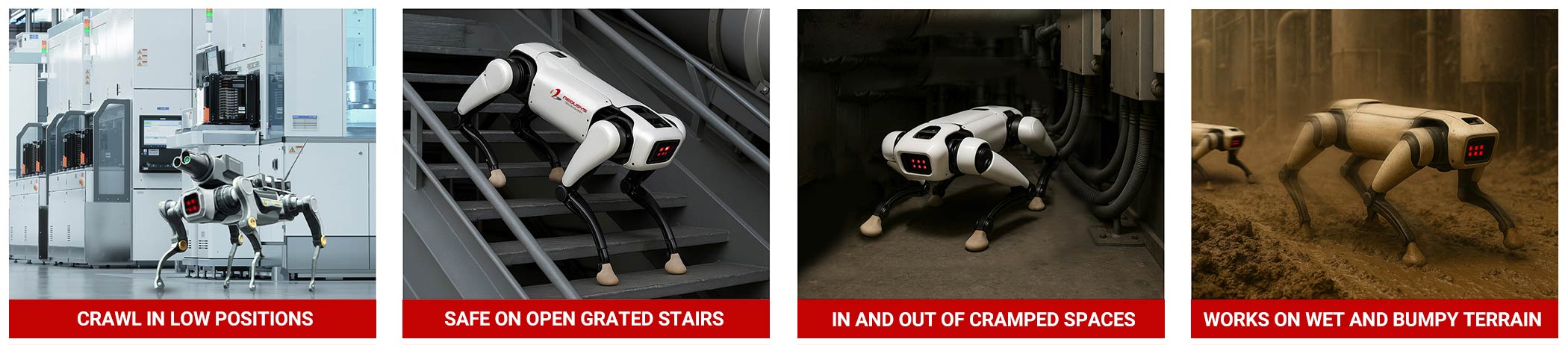

While wheel-based inspection vehicles have long been used in industry, their mobility limitations show in complex environments. Robotic dogs offer significant advantages over traditional wheel-based inspection vehicles in industrial environments due to their superior manoeuvrability across diverse landscapes. Unlike wheel-based vehicles, robotic dogs can navigate stairs, uneven terrain, and tight spaces, making them ideal for complex factory layouts or industrial sites with hard-to-reach areas. Their ability to crawl under machinery, inspect overhead spaces, or traverse narrow hallways enhances operational efficiency by reducing the need for human intervention or specialized equipment.

These robotic systems not only improve safety by reducing human exposure to dangerous or hazardous conditions but also enhance the accuracy and speed of inspections. As a result, robotic dogs offer a more effective, reliable, and efficient solution for inspecting industrial environments, optimizing workflow, and reducing downtime.

"System integration was challenged by the robotic dog’s elongated form factor, limited airflow, and constant vibrations—demanding a compact, fanless, and rugged computing solution with reliable connectivity."

To address these challenges, a computing solution was required that not only fits the robotic dog’s slim frame but also delivers high-performance processing, reliable connectivity, and resilience to harsh operating conditions. The system needed to support diverse sensors, operate without active cooling, and withstand continuous movement and vibration without compromising functionality.

The Neousys FLYC-300, an ultra-compact and 298g light weight NVIDIA® Jetson edge AI computer offering up to 100 TOPS AI computation performances was integrated. The platform has Ethernet, USB3.2, GMSL2 ports that can connect to cameras and sensors like RGB, hyperspectral, infrared, LiDAR, and 3D cameras. The connectivity makes it ideal for real-time video analytics applications such as imagery analysis, environment monitoring, and infrastructure monitoring. The system also accommodates 5G/ 4G or WiFi wireless communication modules for live imagery and video transmission; accepts a wide voltage input range from 4S to 14S battery packs via the XT30 DC-IN connector, and is MIL-STD-810H standard certified to withstand shock and vibration operating environments, making it the perfect ultra-compact AI system to be integrated into the robotic dog.